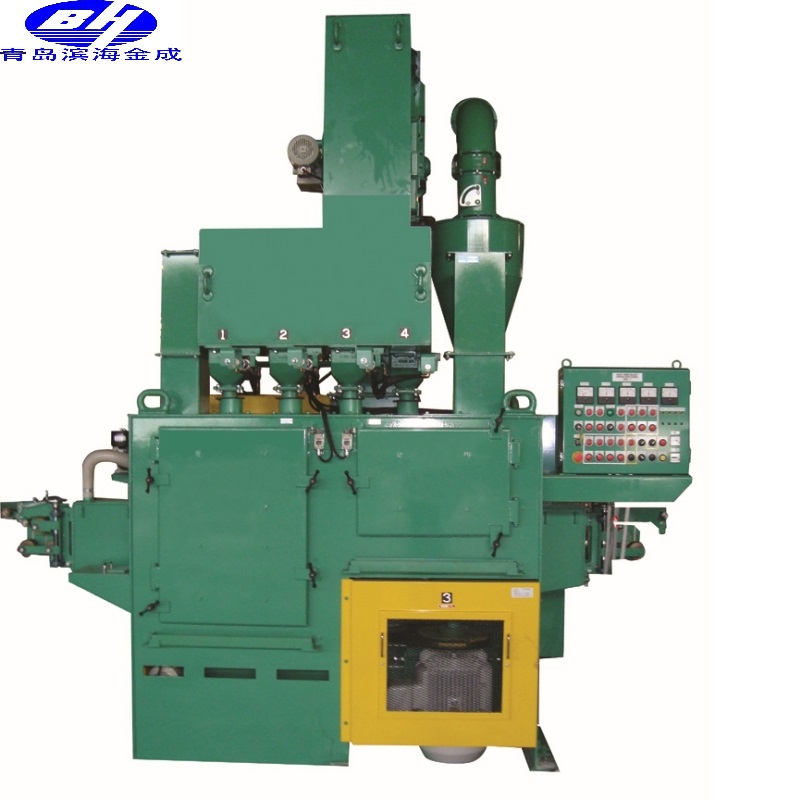

Makina owombera chitoliro chachitsulo

Makina owombera chitoliro chachitsulo

Chitsulo chitoliro kuwombera kuphulitsa makina ndi mtundu watsopano wa zida kuwombera wapadera kuwombera anakonza zofuna wosuta, amene makamaka ntchito kuyeretsa khoma lakunja lalikulu zozungulira zitsulo mipope ndi mphepo nsanja mphepo mphepo, ndi zina kuyeretsa mkati ndi kunja makoma pamwamba. za zitsulo mapaipi.Kudzera kuwombera kuphulika, osati kuchotsa dzimbiri, sikelo, kuwotcherera slag, kuponyera mchenga padziko workpiece, komanso kuchepetsa nkhawa mkati workpiece, kusintha kutopa kukana workpiece, kupanga pamwamba pa workpiece. zitsulo ndi kuonjezera pamwamba pa workpiece Kumamatira kwa filimu ya utoto panthawi yojambula kumapangitsa kuti chitoliro cha chitsulo chisawonongeke ndi chitsulo chozungulira ndikutalikitsa moyo wautumiki wa workpiece.Ndipo potsiriza kukwaniritsa cholinga kuwongolera lonse pamwamba ndi mkati khalidwe mapaipi.

| Tech data | QGW20-50 | QGW80-150 | |

| Konzani kukula kwa chubu (mm) | 30-500 | 250-1500 | |

| Kuthamanga kwa abrasive (kg/min) | 2x260 | 2x260 | 2x750 |

| Liwiro loyeretsa (m/mim) | 0.5-4 | 0.5-4 | 1-10 |

mbali yaikulu ya Zitsulo chitoliro kuwombera kabotolo makina

1. Chida chowombera chowombera chimatengera dongosolo lowombera m'mwamba.Chifukwa pansi padziko zitsulo chitoliro ndi diameters osiyana imaperekedwa pa tebulo wodzigudubuza pa msinkhu womwewo, kuwombera blaster akuwombera kuchokera pansi mpaka pamwamba, ndi mtunda pakati pa abrasive ndi pamwamba pa chitoliro zitsulo ali chimodzimodzi, kuti ndi, kuyeretsa kwenikweni ndi yunifolomu.

2. The workpiece mosalekeza akudutsa polowera ndi potulukira wa kuwombera kuphulitsa makina.Chifukwa cha kuyeretsedwa kwa chitoliro chachitsulo chokhala ndi m'mimba mwake waukulu, pofuna kupewa kuti abrasive asawuluke kunja, makinawa amagwiritsa ntchito burashi yosindikizira yamitundu yambiri kuti akwaniritse chisindikizo changwiro kwa abrasive.

3. Kugwiritsa ntchito makina a centrifugal cantilever apamwamba kwambiri opangira makina ambiri owombera, kuphulika kwakukulu, kuphulika kwakukulu, kugwiritsa ntchito bwino kwambiri, kubwezeretsa tsamba mwachangu, ndikusintha konseko, kukonza kosavuta.

4. Chifaniziro chofananira cha abrasive (kuphatikizapo kutsimikiza kwa chitsanzo, chiwerengero ndi malo opangira makina owombera) ndi zojambula zonse za makina owombera kuwombera zimakokedwa kwathunthu ndi mapangidwe opangidwa ndi makompyuta.Kuchuluka kwa magwiritsidwe ntchito ndi zokolola za abrasive zimatheka, kuyeretsa kumatsimikizika, ndipo kuvala pa mbale yoteteza chipinda kumachepetsedwa.

4. Chophimba chonse cha BE-mtundu wa slag separator chimagwiritsidwa ntchito, chomwe chimathandiza kwambiri kulekanitsa kuchuluka kwa kulekanitsa, kulekanitsa bwino ndi kuwombera khalidwe lakuwombera, ndi kuchepetsa kuvala pa chipangizo chowombera kuwombera.

5. Pulatifomu yachitsulo ya Mn13 imagwiritsidwa ntchito poteteza chipinda choyeretsera, ndipo mbale yotetezera imayikidwa ndi mtedza wapadera.Ndizosavuta komanso zosavuta kusintha ndipo zimakhala ndi moyo wautali wautumiki.

6.Kutumiza mzere wolumikizana

Mzere wolumikizira ukhoza kuzindikira kuwongolera kwa liwiro lopanda masitepe kudzera pa ma frequency converter.Pofuna kuonetsetsa kuti mipope zitsulo za specifications zosiyanasiyana amawomberedwa pa liwiro lodziwika, chitoliro zitsulo ali ndi nthawi zokwanira zobweza mu kuwombera kuphulika chipinda kupeza bwino kuwombera kuphulika kwenikweni.

Kusintha kwa malo odzigudubuza kumachitidwa ndi chipangizo chosinthira.Gulu lililonse lodzigudubuza limalumikizidwa ndi ndodo yolumikizira, kuti kusintha kwa synchronous kutheke.Njira yosinthira imatha kusinthidwa malinga ndi ma diameter osiyanasiyana a chitoliro malinga ndi zomwe wogwiritsa ntchito amafuna.

Wodzigudubuza aliyense amatha kuzungulira pakati pa bulaketi kuti asinthe ngodya yake kuti ifike komwe akudutsa.Pamene liwiro la wodzigudubuza limakhala lokhazikika, liwiro lotumizira ndi liwiro la kuzungulira kwa workpiece zimasinthidwa.Mbali ya wodzigudubuza imasinthidwa mofanana ndi makina a ratchet ndi pawl.

Mphamvu ya wodzigudubuza aliyense imapangidwa ndi chochepetsera, ndipo manambala osiyanasiyana ochepetsera amatha kukonzedwa molingana ndi zofunikira zamagetsi.Bwalo lakunja la wodzigudubuza ndi mphira wolimba, womwe uli ndi kusungunuka komanso kukana kuvala ndipo ukhoza kuthandizira bwino chitoliro chachitsulo.

7, Chitoliro chachitsulo chimasunga kasinthasintha.

8, Wotolera fumbi amatengera zoteteza chilengedwe kugunda katiriji katiriji blowback fumbi.Wosonkhanitsa fumbi ali ndi malo aakulu osefera ndi zotsatira zabwino zosefera.

9, Kapangidwe ka makina ndi kamangidwe kake, kosavuta kugwiritsa ntchito komanso kukonza.

10, Kugwiritsa ntchito chipangizo chodziwira zolakwika kuti muzindikire ntchito ya alarm yotseka.Makinawa ali ndi mawonekedwe apamwamba, kapangidwe koyenera, ntchito yodalirika komanso magwiridwe antchito apamwamba.

11, Popanda dongosolo dzenje, kukonza zosavuta.

Chitsulo chitoliro kuwombera kuphulika makina Makhalidwe

1.kuyeretsa ndandanda

Kutsegula (zoperekedwa ndi ogwiritsa ntchito) → mzere wolumikizira → lowetsani chipinda chowombera → chowombera (chogwirira ntchito chimazungulira chikuyenda) → chipinda chowombera chowombera → mzere wolumikizira → kutsitsa (kuperekedwa ndi ogwiritsa ntchito)

2.Abrasive Circulation Sequence

Kusungirako Abrasive → Kuwongolera Mayendedwe → Chidutswa Chowombera Chowombera → Nyamulani Chokweza Chidebe → Kupatukana kwa Pellet → (Kubwezeretsanso)

4. Makhalidwe apangidwe

Mapangidwe a makinawa amakhala ndi tebulo lodzigudubuza (mamita 12), makina owombera owombera, tebulo lodyera (mamita 12), makina owongolera mpweya, makina owongolera magetsi ndi njira yochotsera fumbi.

Makina owombera owombera amapangidwa ndi chipinda chowombera chowombera, chowombera chowombera, chowombera chowombera, cholekanitsa chowombera, chikepe, njanji yamakwerero, makina owombera ndi zinthu zina.