BHQ26 mndandanda sandbast nduna ndi Buku

1.Kodi sand blast cabinet ndi chiyani

Anthu ena amatchanso makina opukutira mchenga, thanki yophulitsa mchenga, blaster yamchenga yonyamula, makina otsegula mchenga ndi zina zotero.Mayinawa ndi osiyana, koma ali ndi tanthauzo lofanana.Ikhoza kugwira ntchito mosiyana, koma nthawi zambiri imagwira ntchito ndi chipinda chowombera.

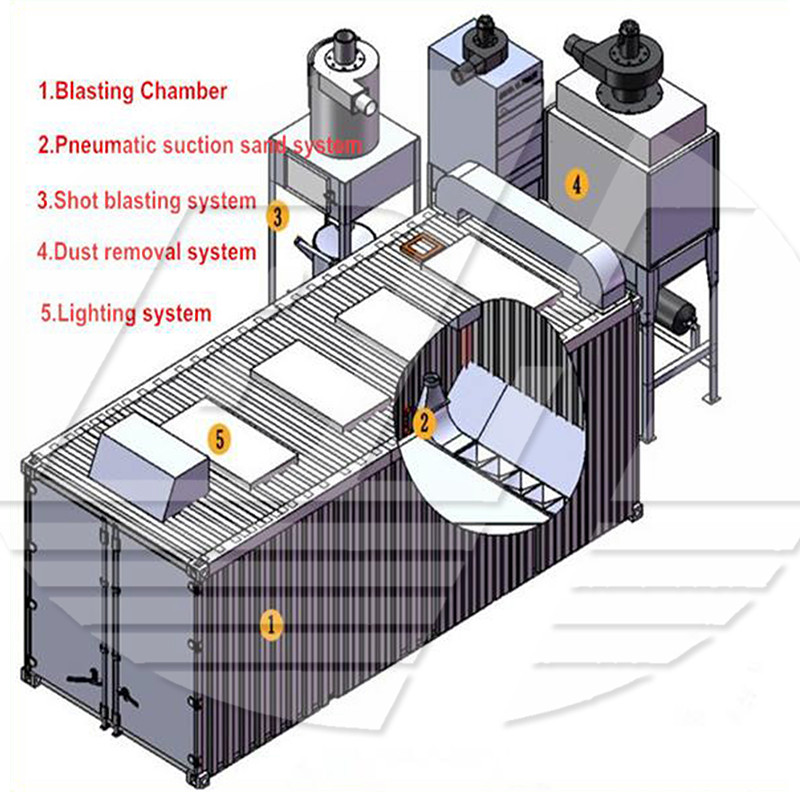

Kupangidwa kwa sand blast cabinet --

Kawirikawiri, zigawozo zili monga:

1).tank yoboola mchenga:

Makulidwe a mbale yachitsulo yomwe amagwiritsidwa ntchito pamitundu yosiyanasiyana ya tanki ndi muzu wa makina opukutira mchenga ndi wosiyana.Kuchuluka kwa voliyumu, m'pamenenso zitsulo zachitsulo zimakhala zokhuthala.Izi makamaka zimatsimikiziridwa ndi fakitale yotengera zotengera zokakamiza malinga ndi momwe zilili.

Pali mitundu iwiri ya valve ya mchenga ndi valavu ya mchenga: manual kapena pneumatic.Pamanja, m`pofunika pamanja kutsegula valavu mchenga, ndi mpweya basi anatsegula ndi mpweya.

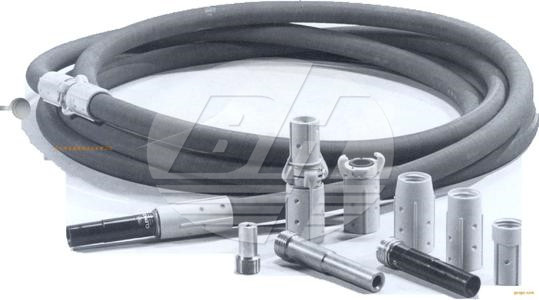

2) chitoliro cha mchenga (muyezo ndi 10m/20m)

3) .Vavu yachitetezo

Kugwiritsa ntchito tanki yopukutira mchenga kumakhala 8KG.Udindo wa valavu yachitetezo Pamene kuthamanga kwa gasi kupitilira 8KG, kumangowonongeka.Pofuna kuteteza thanki ya mchenga

4) .Mfuti ya mchenga: Malingana ndi zinthuzo, zikhoza kugawidwa mu boron carbide, alloy zitsulo, tungsten carbide, chitsulo ndi zina zotero.

Chokhazikika kwambiri ndi boron carbide, ndipo moyo wautumiki nthawi zambiri umakhala maola 500-700.

Kachiwiri, moyo wautumiki wa tungsten carbide ndi zitsulo za aloyi nthawi zambiri zimakhala maola 300-400,

Chitsulo chingagwiritsidwe ntchito kwa maola 10 okha, anthu ochepa azigwiritsa ntchito.

Electronic control system ndi zigawo zina.

2.Mfundo yogwirira ntchito ya sandblaster yonyamula

Mfundo yogwirira ntchito ya makina owombera mchenga ndi yosiyana ndi makina owombera.Makina owombera kuwombera amagwiritsa ntchito mphamvu yapakati kuti aphulitse kuwombera.Makina ophulitsira mchenga amayendetsedwa ndi mpweya woponderezedwa ndikupopera ma abrasives (mchenga wachitsulo komanso wopanda chitsulo) pamwamba pa chogwiriracho.Chifukwa cha kupanikizika, abrasive mu thanki yamchenga imadutsa mu valve ya mchenga ndikuphulika chubu kupita ku mfuti ya spray, ndipo abrasive imatulutsidwa pa liwiro lalikulu, zomwe zimasintha makina a kunja kwa workpiece pamwamba.Chifukwa cha kukhudza ndi kudula zotsatira za abrasive pa workpiece pamwamba , Kupeza mlingo wina wa ukhondo ndi roughness osiyana pamwamba pa workpiece, kusintha mawotchi zimatha workpiece pamwamba, kotero kusintha kutopa kukana workpiece, kuonjezera zomatira pakati pa izo ndi ❖ kuyanika, ndi kukulitsa ❖ kuyanika Kukhalitsa kwa filimuyi kumathandizanso kuti musamalidwe ndi kukongoletsa kwa ❖ kuyanika, kuchotsa zonyansa, phokoso ndi oxides pamwamba, pamene roughening pamwamba pa sing'anga, kuchititsa kupsinjika kotsalira pa gawo lapansi ndikuwongolera kuuma kwa gawo lapansi.

3.Main specifications for portable sand blaster

4. Kutaya mphamvu kwa thanki yowombera

1).Kusintha kwa mpweya wa makina opangira mchenga nthawi zambiri ndi 6m³/mphindi (kugwiritsa ntchito mpweya wamfuti imodzi yopopera, ngati ndi N, kasinthidwe ka mpweya wofunikira ndi N*6m³/min.

| Mtundu wa chinthu | Q0250 | Chithunzi cha Q0250A-Ⅱ | Chithunzi cha Q0250A-Ⅱ-LX | ||

| Kuchuluka kwa tanki (m3) | 0.5 | 0.7 | 0.82 | ||

| Air pressure (Mpa) | 0.5-0.6 | 0.5-0.6 | 0.5-0.6 | ||

| Mlingo wotulutsidwa (caliber=φ10)(kg/h) | 1800-2280 | 1 mfuti | 1800-2280 | 1 mfuti | 1800-2280 |

| 2 mfuti | 3600-4560 | 2 mfuti | 3600-4560 | ||

| Kugwiritsa ntchito mpweya (m3/mphindi) | 6.1 | 1 mfuti | 6.0 | 1 mfuti | 6.0 |

| 2 mfuti | 12.0 | 2 mfuti | 12.0 | ||

| Utali wa chitoliro chophulika (mm) | 7000 | 7000 (2pcs) | 7000 (2pcs) | ||

| Control njira | Kuwongolera kutali | Kuwongolera kutali | Kuwongolera kutali | ||

| kukula (mm) | 1036*812*1860 | 1120*900*1890 | 1086*812*2060 | ||

| Kulemera (kg) | 396 | 500 | 690 | ||

2).Kuthamanga kwa mpweya komwe kumafunidwa ndi makina opangira mchenga ndi 0.5-0.6mpa (ngati kupanikizika kuli kochepa kwambiri, mchenga wa mchenga udzakhala wofooka ndipo zotsatira zoyeretsa zidzakhudzidwa).

3).Kuchuluka kwa mchenga / kuwombera pa ola la makina opangira mchenga ndi 1800-2100 kg.

4) Ntchito osiyanasiyana sandblasting

a.Chithandizo chisanachitike: mankhwala onse ophulika asanaphimbidwe, monga electroplating, kupaka utoto, kupopera mbewu mankhwalawa, ndi zina zotero, pamwamba pake ndi oyera, ndipo nthawi yomweyo amathandizira kwambiri kumamatira ndi kukana kwa dzimbiri kwa chophimbacho.

b.Pre-mankhwala pamaso kuyeretsa pamwamba pa mbali: descaling, zotsalira ndi dothi mbali zitsulo monga castings, stamping mbali, kuwotcherera mbali, kutentha kutentha mbali;Kuyeretsa pamwamba pa zinthu zopanda zitsulo, kuchotsa mawanga akuda pamwamba pazitsulo za ceramic ndi kuchepetsa utoto Chitsanzo, etc.

c.Kukonzanso kwa zigawo zakale: kukonzanso ndi kuyeretsa mbali zonse zosuntha monga magalimoto, njinga zamoto, zida za electromechanical, etc. Panthawi imodzimodziyo kuthetsa kutopa ndi kukulitsa moyo wautumiki.

d.Kumaliza kukonza pamwamba pa workpiece: zitsulo zonse ndi zinthu zopanda zitsulo (pulasitiki, kristalo, galasi, ndi zina zotero) zowonongeka zimachotsedwa, ndipo chithandizo cha argon chifunga chimapangitsa kuti mankhwalawo apitirire.

e.Chithandizo cha nkhungu: Argon kuwala chifunga pamwamba chithandizo cha nkhungu pamwamba, zojambulajambula, ndi kuyeretsa nkhungu, osati kuwononga nkhungu pamwamba, kuonetsetsa kuti nkhungu yolondola.

f.Chithandizo cha Burr: Magawo opangidwa ndi makina amachotsedwa ndi ma burrs ang'onoang'ono, ndipo magawo apulasitiki a jekeseni amachotsedwa.

g.Kukonzanso kwa zinthu zosafunikira: kuchotsedwa kwa zinthu zosafunikira zokutira, kuchotsa utoto wosafunika pamwamba ndikuchotsa kusindikiza.

h.Kulimbitsa: kuonjezera kuuma kwazitsulo zazitsulo ndikuchotsa kupsinjika, monga chithandizo chapamwamba cha masamba a ndege, akasupe, zida zamakina ndi zida.

ndi.Etching ndi anti-skid processing: etching mapatani, zolemba ndi anti-skid mankhwala pamwamba pa zinthu zitsulo ndi zinthu zopanda zitsulo, monga: nsangalabwi, odana skid handles, zisindikizo, stele lettering, etc.

j.Chithandizo cha zovala za denim: Zovala za denim ndizowoneka bwino, zoyera komanso zandevu zamphaka zimakwaniritsidwa.

5. Ubwino wa sandblast cabinet:

1).Zigawo zachitsulo za makina opangira mchenga sizinawonongeke, ndipo kulondola kwazithunzi sikudzasintha;

2).Pamwamba pa gawolo sichidaipitsidwa, ndipo abrasive sichidzakhudzidwa ndi mankhwala ndi zinthu za gawolo;

3).Makina opangira mchenga amatha kuthana mosavuta ndi magawo osafikirika monga grooves ndi concaves, ndi kukula kwake kosiyanasiyana kwa abrasives kungasankhidwe kuti agwiritse ntchito;

4).The processing mtengo kwambiri yafupika, makamaka kusonyeza kusintha kwa ntchito dzuwa la sandblasting makina, amene angathe kukwaniritsa zosiyanasiyana padziko kutsirizitsa zofunika;

5).Kugwiritsa ntchito mphamvu zochepa komanso mtengo wotsika;

6).Makina opangira mchenga saipitsa chilengedwe, kuthetsa mtengo wa chithandizo cha chilengedwe;